PLM

Product Lifecycle Management, or PLM,

Product Lifecycle Management, or PLM,

is a driver of successful product development, and a strategic contributor to business value across the enterprise. PLM helps product manufacturers manage complex, cross-functional processes, coordinating the efforts of distributed teams to consistently and efficiently create the best possible products.

The principal role of Product Lifecycle Management (PLM) is to manage a product’s definition from concept to retirement.

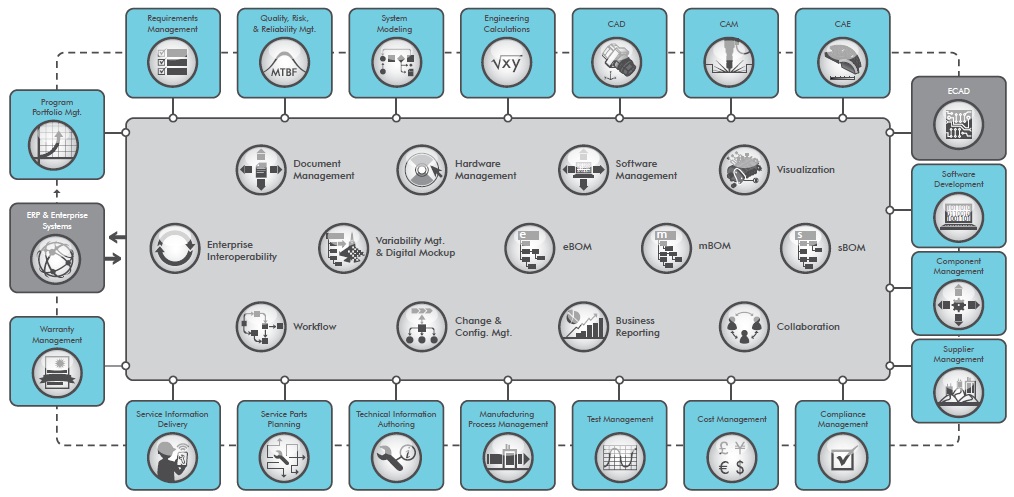

To be effective, PLM solutions must completely define all aspects of the product’s Bill of Materials (BOM) – including mechanical and electrical design files (MCAD, ECAD), software, documentation, and service information. PLM enables the definition and synchronization of cross-functional views of the BOM: engineering (eBOM), manufacturing (mBOM), and service (sBOM).

Directly, PLM offers significant value to a company, but PLM also enhances other enterprise systems (ERP, CRM) by enabling the sharing of product information throughout the organization.

PLM offers broad and deep capabilities, including:

- Requirements management

- Product data management

- Visualization and digital mockup

- Program & portfolio management

- Change and configuration management

- Manufacturing process management

- Quality management

The result is improved profitability through:

- Increased revenue via successful product introductions

- Reduced product and development cost

- Accelerated time to market

- Improved product quality